From CNC machining to 3D printing, we deliver precision manufacturing solutions with quality and reliability.

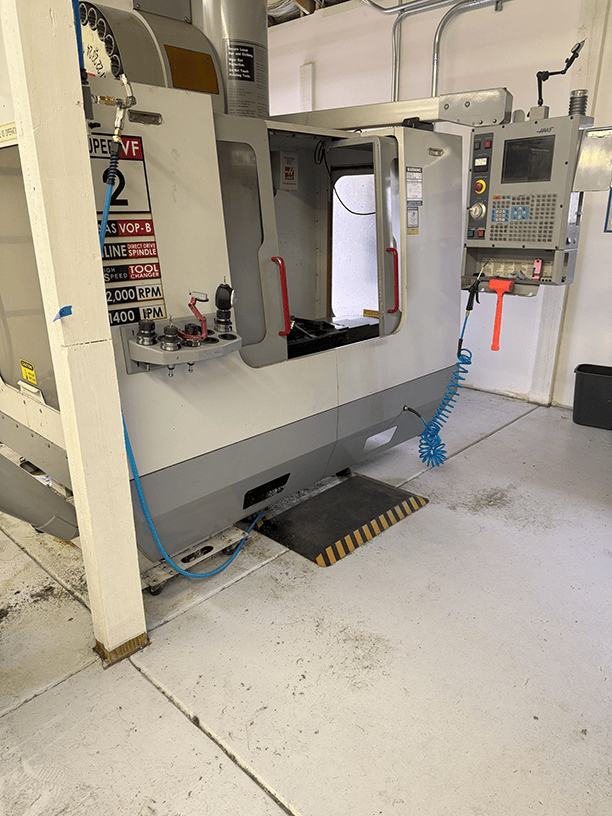

Precision CNC machining using HAAS VF2 vertical machining centers with 4th axis capabilities. Expert machining services for complex parts with tight tolerances and reliable results.

Precision Swiss machining using our Citizen L20 VII Swiss lathe with 12-foot bar feeder. Ideal for small, complex parts requiring exceptional precision and repeatability.

Complete engineering and design services to bring your concepts to life. From initial design to production-ready parts, we provide comprehensive engineering solutions.

Advanced 3D printing services using our Bambu Labs X1-Carbon combo printer. Perfect for prototyping, custom parts, and low-volume production runs.

We invest in quality equipment to ensure the precision and consistency of every part produced: